Supersonic Science in SDSU's Wind Tunnel Complex

This advanced facility is often used to refine products aerodynamics and test new scientific concepts.

Grant Imahara, co-host of Netflix’s “Mythbusters” spin-off television show “White Rabbit Project,” watches as a team of scientists put a model dragster into what looks like a small room. At the press of a button and flick of a switch on the control center outside, wind loudly floods the room while computers analyze the way the air flaps and folds around the racecar’s curves. “You hear that?” Imahara shouts over the deafening roar. “That’s the sound of science!”“The wind tunnel facility at San Diego State has been and will continue to be a vital asset to our aerospace engineering education and research programs.”

San Diego State University’s wind tunnel was built in 1963, a sprawling complex of sheet metal and wood panels that starts at ground level and loops through a basement originally built as a bomb shelter in the engineering building. Despite its age and cobbled-together look, constant technological updating has made it one of the most advanced wind tunnel testing facilities in the Southern California region.

That’s why Imahara and the “White Rabbit Project” team chose to film part of their episode “Speed Freaks” at the SDSU facility last year, demonstrating how scientists use wind tunnels to test and refine the aerodynamics of some of the world’s fastest vehicles. By precisely tweaking a racecar’s scooped wings and paneling, engineers can keep the wheels optimally pressed to the ground, transferring as much energy from the motor as possible and preventing the car from flying up during a race.

But it's not typically Hollywood television shows that use SDSU’s facility; more often it’s national and local companies using the wind tunnel to analyze the aerodynamics of everything from airplane wings to golf clubs.

“We have great relationships and partnerships with industry,” said Gustaaf Jacobs, a professor of aerospace engineering who manages the facility and uses the wind tunnel for his own research.

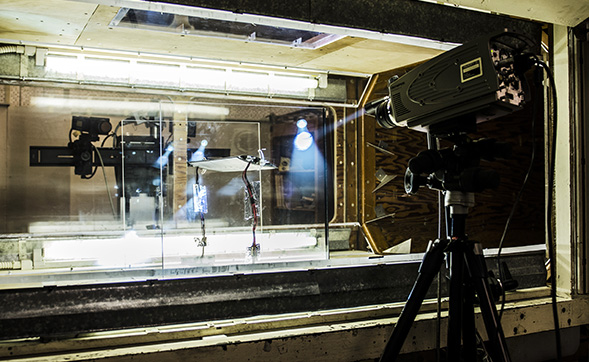

There are actually two wind tunnels that make up the facility. The enormous low speed tunnel—the one shown in the episode—has a top wind speed of 165.93 miles. A force plate in the three-by-four-foot chamber measures how the wind acts on the object. By spraying aerosolized olive oil into the chamber and bouncing a sheet of lasers through the chamber, users can see and analyze minute airflow patterns.

A second, more compact supersonic wind tunnel is down the hall. Its wind speeds can reach more than four times the speed of sound concentrated on a six-square-inch chamber. This tunnel has been used to measure the aerodynamics of bullets and other extremely high-velocity objects.

Aside from industry uses, students and researchers also routinely use the wind tunnel for academic projects, including recent projects examining the aerodynamics of wildfire movement, wind turbines, racecar airfoils and drone rotors and wings. This wide diversity of uses ensures SDSU’s students and scientists, as well as industry partners, will continue to use the facility to test products and make new discoveries well into the future.

“The wind tunnel facility at San Diego State has been and will continue to be a vital asset to our aerospace engineering education and research programs,” said Ping Lu, chair of the aerospace engineering department. “At the same time, we welcome local industry to come to take advantage of this unique facility when their business calls for it.”