Optimizing Extraterrestrial Construction and Repair

SDSU engineers are optimizing the processes to build materials in space

The article first published in the 2022 edition of Highlights: A Magazine of Research, Scholarship and Creative Activities at SDSU.

You're halfway through the 71 million mile flight between Earth and Mars when all of a sudden the "check engine" light comes on.

A piece of your spacecraft broke and you need to repair it or manufacture a new part to continue on with your journey. But how do you repair it in the middle of outer space?

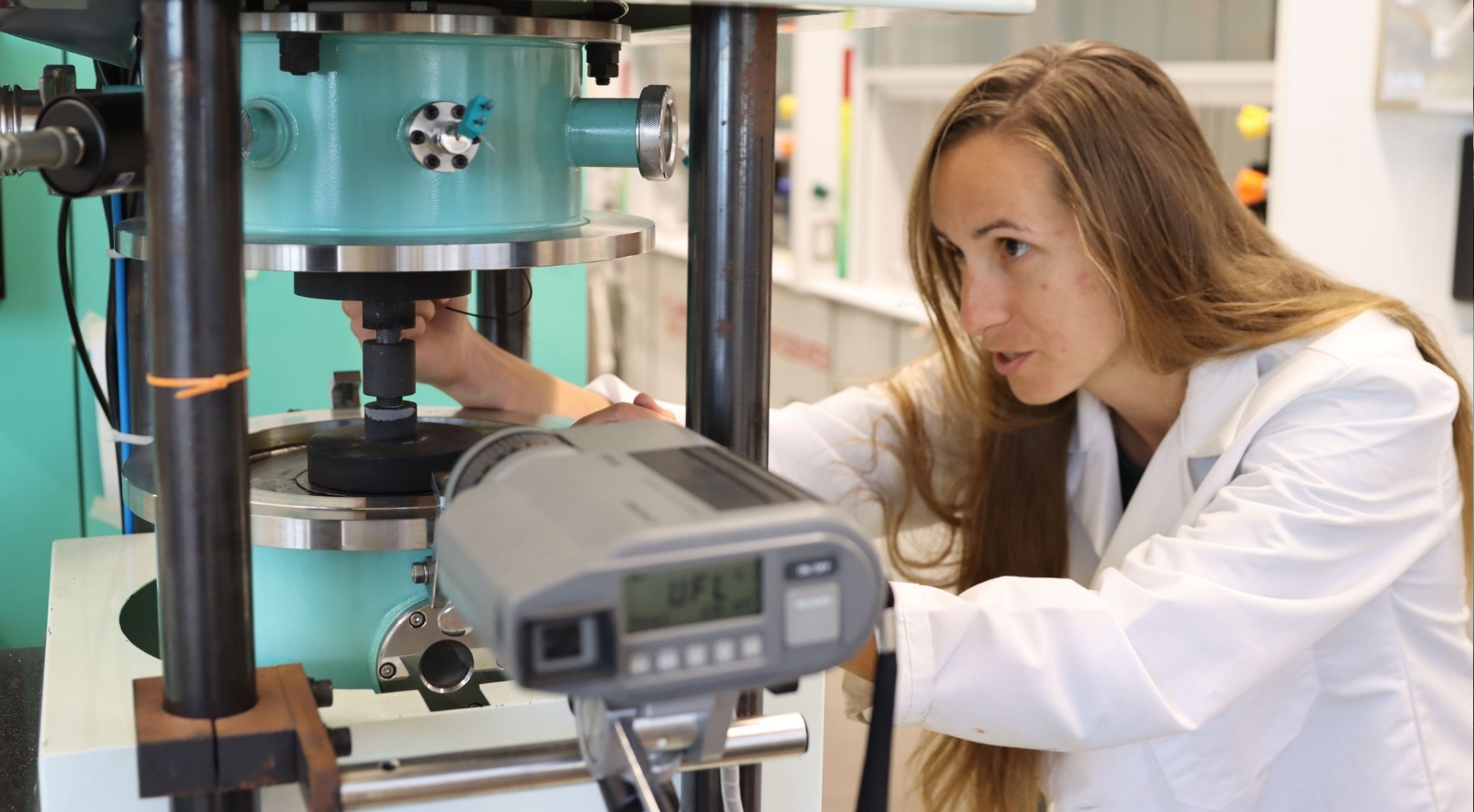

In research supported by NASA, San Diego State University mechanical engineers Eugene Olevsky, Elisa Torresani and Randall German are studying how to manufacture and repair materials outside of earthly gravity conditions and ensure that when this zero gravity scenario happens in the future, we’ll be equipped with the best tools and processes.

Olevsky and Torresani lead the Powder Technology Laboratory at SDSU, which focuses on sintering. Sintering is a technique used to turn a powdered material into a solid mass by heating and compressing it in a furnace chamber. It is broadly used to produce metallic and ceramic parts and can be used in applications such as diamond-cutting tools and drill bits — but the possibilities don’t end there.

Their latest project targets the process of sintering itself, and aims to look forward to when fabrication and repair operations will be necessary in a zero gravity environment, such as a space station, space vehicle traveling from Earth or a futuristic world of extraterrestrial settlements.

As humans expand into space, construction materials will be essential. Yet transporting materials from earth to space would be too burdensome and costly.

“Every mass sent to space is incredibly expensive to transport,” said Olevsky, dean of the College of Engineering. “So we need to find something right in space. Something like moon dust. And we need a means of transforming that material.”

Enter sintering.

The team set off to sinter model materials, including heavy alloys, into structures to understand how to sinter in outer space conditions. Heavy alloys consist of tungsten with a nickel-iron or nickel-copper matrix and are the quintessential ingredient to produce a strong and well-shaped part or component using sintering — at least on Earth.

“On earth, the mass of heavy alloys is critically affecting the sintering process, creating a gravitational pressure that helps form the solid material. But what will this process look like in zero gravity environments?” asked Olevsky.

Additional exploration

That’s just one of the questions the research team is investigating. The engineers are also exploring the use of new materials in the sintering process, and ways to counter the impact of low gravity and improve the quality of sintered components.

The moon’s gravitational force is approximately one-sixth that of Earth, meaning that lunar-sintered products are more likely to be weaker components with distortion of shape and density differences.

“This research will help us predict how sintering operations would work under low gravity conditions, and help us determine the most effective solutions to distortion and defects so that sintering might become a useful tool in space,” said Torresani, an assistant professor of mechanical engineering.

The team of scientists has been working together since 2019 to create novel materials out of NASA’s extraterrestrial sintering furnace in the International Space Station (ISS) — testing the process in zero gravity environments, and measuring density and microstructures in the sintered material for weaknesses. Torresani worked alongside researchers at NASA's Marshall Space Flight Center, sending instructions up to the ISS. And using computer modeling, the team calibrated their existing on-earth models with the results to project how the materials would react in space, or in the absence of gravity.

Findings signaled many differences between sintering in space and on earth: among other things, materials sintered in space were less dense — the highest result in a sintered composition was 90% of the ideal theoretical density, meaning the materials are more likely to crack, a dealbreaker when they’re used as part of a machine or building.

Their findings provide an essential baseline for whether sintering can be leveraged in outer space.

Next steps? How to optimize sintering conditions to produce high quality materials. The team is seeking continued funding to determine if extraterrestrial manufacturing can be optimized by adding 3D printing techniques into the mix.